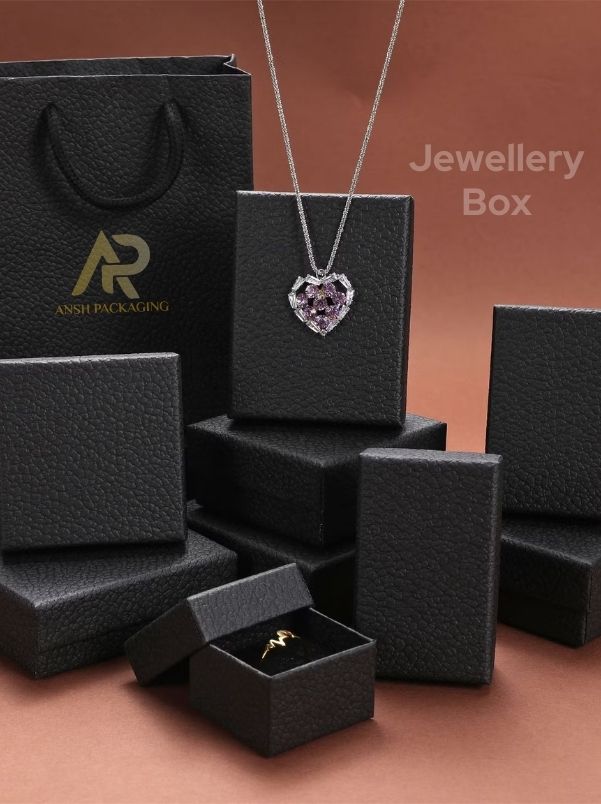

Mono Carton Box Manufacturers

Mono Carton Box Manufacturers:- The packaging industry is currently experiencing an unprecedented demand for solutions that are efficient, durable, and environmentally friendly. Among the most favored options that fulfill these criteria is the Mono Carton Box Manufacturers These boxes are extensively utilized across multiple sectors owing to their robustness, adaptability, and economic viability. As companies place greater emphasis on sustainability and cost efficiency, the significance of mono carton box manufacturers has become crucial within the packaging sector. This article will delve into the significance of mono carton boxes, the manufacturing process involved, and the advantages of collaborating with mono carton box manufacturers.

A Mono Carton Box Manufacturers refers to a packaging solution constructed from a single layer of cardboard or paperboard. In contrast to other packaging forms that incorporate multiple layers or various materials, mono cartons are formed from one continuous sheet that is subsequently folded into a box configuration. This straightforward yet efficient design renders mono carton boxes lightweight, robust, and environmentally sustainable.

These boxes are frequently utilized for packaging an extensive array of products, such as food items, electronics, cosmetics, pharmaceuticals, and beyond. They offer an optimal combination of protection, aesthetic appeal, and affordability.

The Production Process of Mono Carton Box Manufacturers

The production of mono carton boxes encompasses multiple stages that demand accuracy and meticulousness. Below is a detailed outline of how manufacturers of mono carton boxes develop these packaging solutions:

Material Selection: The initial phase in the production process involves choosing the suitable material. Mono carton boxes are generally constructed from recycled paperboard or corrugated cardboard. The selection of material is influenced by factors such as the weight of the product, its fragility, and the degree of protection needed during transportation.

Pulping and Forming: During this phase, the paperboard or cardboard is processed through pulping, which entails breaking down wood fibers and mixing them with water. This resulting pulp is subsequently pressed and dried to create sheets of paperboard. The thickness of these sheets is crucial for ensuring the box’s strength and resilience.

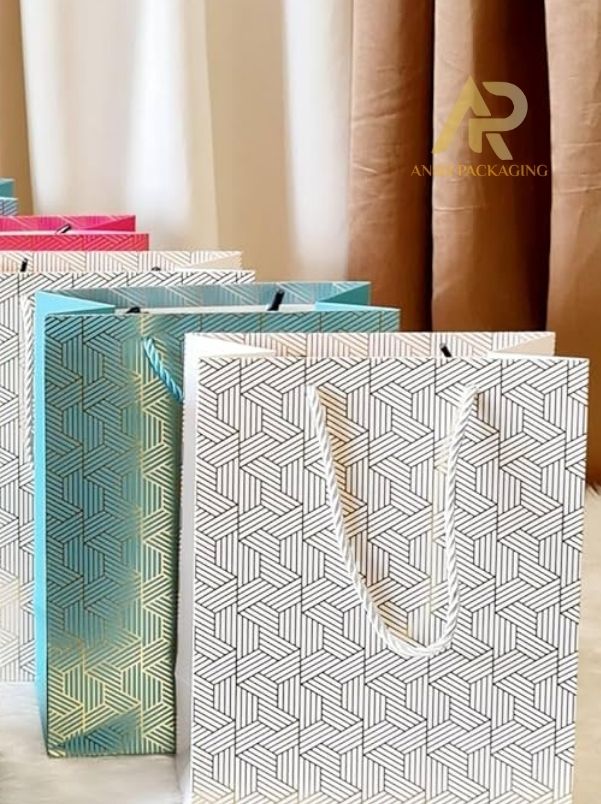

Printing: A significant benefit of mono carton boxes is their ability to provide an excellent surface for printing. This stage allows manufacturers to incorporate branding, product details, or graphics directly onto the cardboard surface. Advanced printing techniques are employed to guarantee that the designs are vibrant and durable.

- NAME: Mono Box

- SPECIFATION: 300 GSM

- MATERIAL: SBS, Kraft Paper

- QUANTITY: 2000

- SIZE: 6X5X3

- DELIVERY TIME: 1/3 Days

- CAPACITY: 100 ML

- COLOR: Multicolor